Table of Contents

The A40640 module is truly the first classic module in the history of dilde laser's innovations for large-scale applications. Its extremely lightweight design and all-around performance for a wide range of engraving and cutting applications provides excellent performance in metal engraving, wood engraving and cutting, acrylic engraving, etc.

The reliability and longevity of the module is greatly enhanced by the A40640 II, which has been designed to provide the most reliable and long-lasting module available. The A40640 II greatly enhances the reliability and longevity of the module, and is designed to be the ultimate in silence, anti-static, temperature control, performance balance and ease of use.

Application Examples

Wood Engraving

https://www.facebook.com/photo/?fbid=1509924309524202&set=pcb.3268776093367444

Basswood photo a40640, neje max

https://www.facebook.com/photo/?fbid=1509924309524202&set=pcb.3268776093367444

Basswood photo a40640, neje max

https://www.facebook.com/photo/?fbid=10222754855039862&set=gm.3295272114051175&idorvanity=2737185006526558

Did another 3D illusion engraving from a purchased design. This one is 8” X 10” on 1/2 inch solid Maple wood. A40640, 2000 mm/m 40% power.

https://www.facebook.com/photo/?fbid=10222754855039862&set=gm.3295272114051175&idorvanity=2737185006526558

Did another 3D illusion engraving from a purchased design. This one is 8” X 10” on 1/2 inch solid Maple wood. A40640, 2000 mm/m 40% power.

https://www.facebook.com/photo/?fbid=158016823876022&set=gm.3450484065196645&idorvanity=2737185006526558

https://www.facebook.com/photo/?fbid=158016823876022&set=gm.3450484065196645&idorvanity=2737185006526558

Wood Cutting

https://www.facebook.com/photo/?fbid=10229359243359174&set=pcb.3760667277511654

4 layers plywood, size 250×250 mm, quarz mechanism. Laser - Neje 2 Max whit A40640 module.

https://www.facebook.com/photo/?fbid=10229359243359174&set=pcb.3760667277511654

4 layers plywood, size 250×250 mm, quarz mechanism. Laser - Neje 2 Max whit A40640 module.

https://www.facebook.com/photo/?fbid=10223826034271146&set=pcb.3091315694446819

The A40640 has been fitted to my MPCNC and is working incredibly well for my application needs. Don't see many using it for my application in the construction of giant scale RC aircraft.

https://www.facebook.com/photo/?fbid=10223826034271146&set=pcb.3091315694446819

The A40640 has been fitted to my MPCNC and is working incredibly well for my application needs. Don't see many using it for my application in the construction of giant scale RC aircraft.

https://www.youtube.com/watch?v=tGGNg63Ntzc&t=199s

A40640 laser module to cut and engrave | I built RC airplane with this

https://www.youtube.com/watch?v=tGGNg63Ntzc&t=199s

A40640 laser module to cut and engrave | I built RC airplane with this

Photo Engraving

https://www.facebook.com/photo/?fbid=2378201085681661&set=pcb.3503723403206044

It's unbelievable what u can do with neje a40640 module ❤️

https://www.facebook.com/photo/?fbid=2378201085681661&set=pcb.3503723403206044

It's unbelievable what u can do with neje a40640 module ❤️

https://www.facebook.com/100004753779137/videos/pcb.3786801458231569/1502786293931811

Old neje laser master 2 max with A40640 module, still doing pretty well after all these years

All are burnt with same settings, speed 2000, 20% power, Stucki mode.

https://www.facebook.com/100004753779137/videos/pcb.3786801458231569/1502786293931811

Old neje laser master 2 max with A40640 module, still doing pretty well after all these years

All are burnt with same settings, speed 2000, 20% power, Stucki mode.

https://www.facebook.com/photo/?fbid=209613958185067&set=pcb.3374265476151838

Decided to try some tile work, these are my test results from day 1, think these will be awesome with some more fine tuning, also thinking the a40640 may be a little powerful this stuff

https://www.facebook.com/photo/?fbid=209613958185067&set=pcb.3374265476151838

Decided to try some tile work, these are my test results from day 1, think these will be awesome with some more fine tuning, also thinking the a40640 may be a little powerful this stuff

Metal Engraving

from Alexis Phipps

Here comes the laser-etched stainless steel bracelet!

Max 4 & A40640

600/70%/2 passes

from Alexis Phipps

Here comes the laser-etched stainless steel bracelet!

Max 4 & A40640

600/70%/2 passes

https://www.facebook.com/photo/?fbid=2090673851105260&set=pcb.3164539797124408

I did some tests on stainless steel.

With module A40640, and comes out not bad at all.

1. On Spatula blade.

2. On an Arcos knife blade.

3. On a cutting knife blade.

Distance 21 mm, speed 600, 100% power.

I also tried on Zippo lighter, 0 results.

https://www.facebook.com/photo/?fbid=2090673851105260&set=pcb.3164539797124408

I did some tests on stainless steel.

With module A40640, and comes out not bad at all.

1. On Spatula blade.

2. On an Arcos knife blade.

3. On a cutting knife blade.

Distance 21 mm, speed 600, 100% power.

I also tried on Zippo lighter, 0 results.

Stainless Steel Engraving

https://www.facebook.com/photo/?fbid=5539845769359844&set=gm.3167431356835252&idorvanity=2737185006526558

Neje A40640 on steinless steel, no coating, size A5

https://www.facebook.com/photo/?fbid=5539845769359844&set=gm.3167431356835252&idorvanity=2737185006526558

Neje A40640 on steinless steel, no coating, size A5

https://www.facebook.com/1497729072/videos/990159728557695/?idorvanity=2737185006526558

Painted Glass Enraving

https://www.facebook.com/1497729072/videos/990159728557695/?idorvanity=2737185006526558

Painted Glass Enraving

https://www.facebook.com/photo/?fbid=279769061017090&set=pcb.3162398900671831

mdf cut

https://www.youtube.com/watch?v=QR6vtpLj0R0

https://www.facebook.com/photo/?fbid=279769061017090&set=pcb.3162398900671831

mdf cut

https://www.youtube.com/watch?v=QR6vtpLj0R0

https://www.facebook.com/photo/?fbid=10158582910011471&set=pcb.3216449251933462

This was done with my A40630 moudule my A40640 module came today and that thing cut Uber fast can’t wait to try the black acrylic. This is called laserette a company name JDS here in the Us sells it fir $3.94 fir a 12×24 sheet which can make it .

Hand sewed now I should have engraved it first lol 😂 I was so excited to sew it together patches want be a problem

https://www.facebook.com/photo/?fbid=10158582910011471&set=pcb.3216449251933462

This was done with my A40630 moudule my A40640 module came today and that thing cut Uber fast can’t wait to try the black acrylic. This is called laserette a company name JDS here in the Us sells it fir $3.94 fir a 12×24 sheet which can make it .

Hand sewed now I should have engraved it first lol 😂 I was so excited to sew it together patches want be a problem

Features

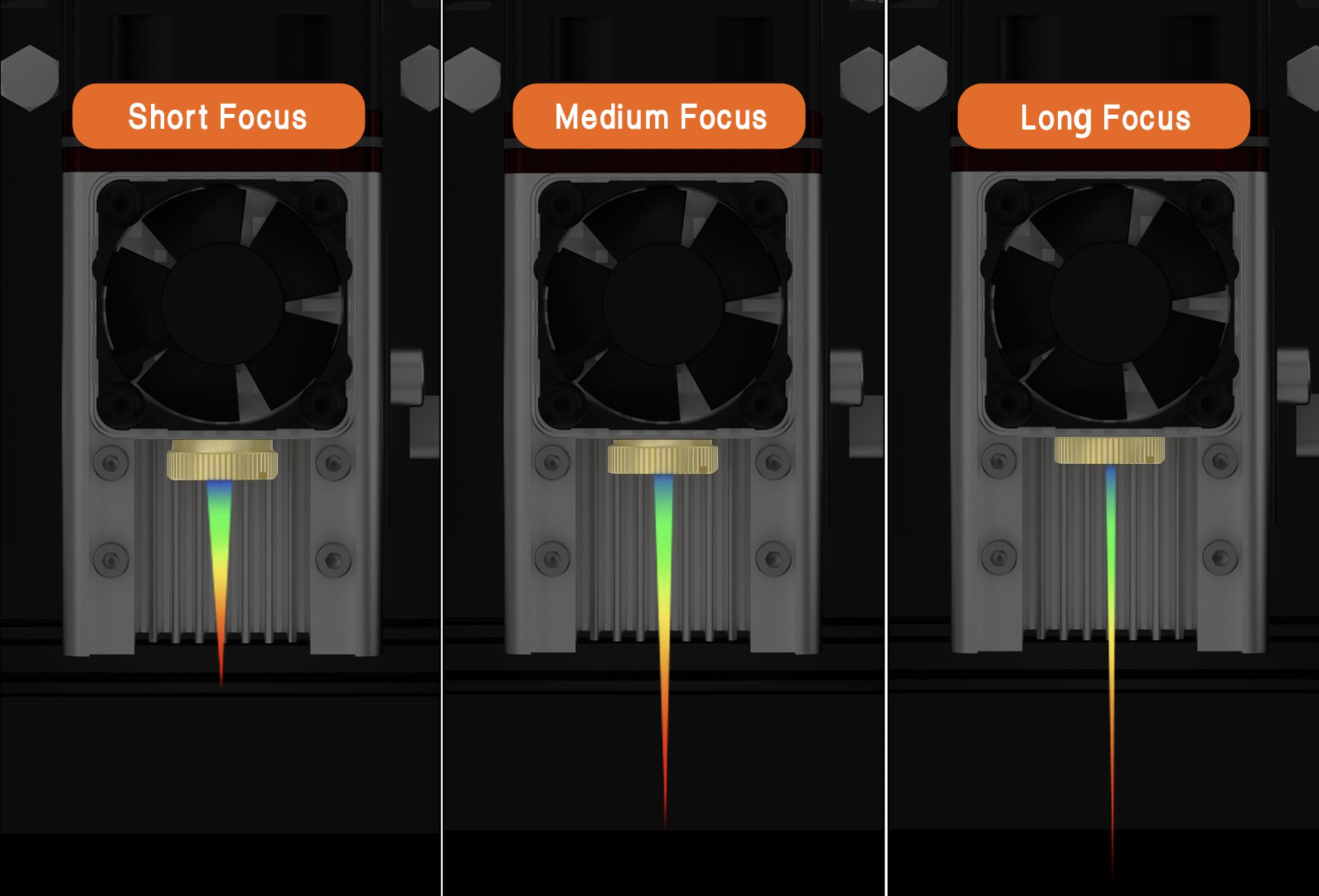

Variable multi-focal length cutter head design

Variable multi-focal length cutter head design

NEJE A40640 is currently the laser module with the best engraving efficiency. The pulse density and knife shape design are especially suitable for high-efficiency engraving. Compared with the same type of laser module, the engraving efficiency is 200% higher. Even under low light conditions, you can hear the focus plasma The sound of hitting, A40640 is also capable of cutting tasks within 20mm, and has a more efficient cutting ability within 8mm.

The NEJE A40640 module is an adjustable focus module. For the consistency of testing, the NEJE factory adjusts the module to 55-70mm focal length by default. This focal length is not the best carving and cutting focal. This focal length is generally not commonly used. When you are suitable for the first use of the product, it is recommended to use a flat-head screw to adjust the focal length to about 10-20mm, which is 10-20mm away from the light baffle. This focal length has a very high focal power density and can directly engrave grayscale stainless steel images\ gray-black stone and other hard materials, NEJE A40640 can directly engrave 3D hardwood and other materials, and does not require air assistance, due to the high energy density design, A40640 can directly vaporize general wooden materials during the engraving and cutting process, so it is also unecessary to add air assist.

Air assist

When do you need air assist

Air-assisted engraving or cutting can only be used for engraving or cutting that produces more carbonized substances. Generally, the depth of engraving is less than 1mm, and the cutting of plywood less than 2mm does not require air assist. A small fan can be used to blow off the smoke generated by the engraving. Air assist is not recommended when engraving images, and adding air assist at this time will destroy image details.

What kind of air pump is suitable for cutting

The main meaning of air assist is to blow off the carbonized material produced by cutting, and the general oxygener and electromagnetic inflator have almost no meaning. only the pressure of the oil pump and air compressor (0.4-1.5mPa) has the effect of blowing away the carbonized material. but it should be noted that the air of the oil pump contains oil and cannot be directly used for the air-assisted module of the closed cavity, otherwise the oil will contaminate the lens, resulting in power drop or damage to the lens. The air pressure of the air compressor can be used for a short time with the closed cavity, but When used for a long time, the water-containing gas will contaminate the lens, cause the power to drop, and even damage the lens.

Database

plywood 2mm cut ———— 480mm/min,S1000, 1 pass

plywood 3mm cut ———— 420mm/min,S1000, 1 pass

plywood 4mm cut ———— 360mm/min,S1000, 1 pass

plywood 5mm cut ———— 240mm/min,S1000,1 pass

plywood 8mm cut ———— 120mm/min,S1000,1 pass

plywood 18mm cut ———— 120mm/min,S1000,3 pass

birch ply 3mm ———— 480mm/min,S1000, 1 pass

MDF board 3mm cut ———— 120mm/min,S1000, 1 pass

MDF board 5mm cut ———— 120mm/min,S1000, 2 pass

MDF board 8mm cut ———— 120mm/min,S1000, 3 pass

black acrylic plate 3mm cut ———— 120mm/min,S1000, 1 pass

black acrylic plate 5mm cut ———— 120mm/min,S1000, 2 pass

Specification

Radiator Size: 40 x 50 x 60 mm

Weight: 204g

Speed of the Fan: 10600RPM (Intelligent speed control based on temperature, effectively reducing noise)

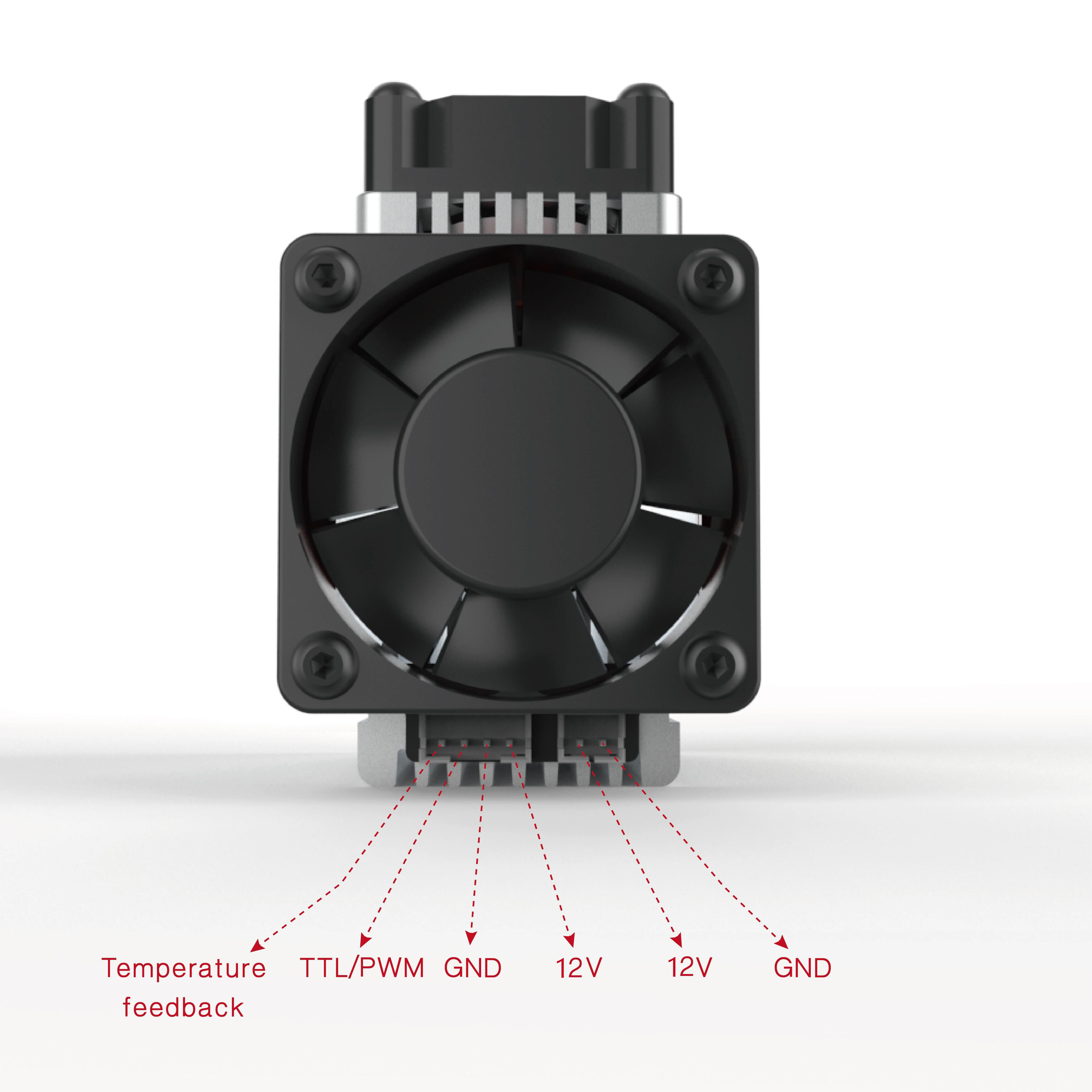

Interface: PH2.0 4Pin+2pin

Drive Design: Built-in

Input: 12V 4A

Optical Power: 12W

Wavelength: 450nm

Laser Class: Class 4

Number of Diodes: 2

Light Source: 2xLD+fiber + FAC Tech + C-Lens

PWM Input: VPP(3.3-12V), Recomend 1KHz

Quiet Design: Drive the built-in control ic, judge the working state and adjust the fan work.

Anti-static technology design: Yes.

Temperature feedback and over-temperature protection: Yes.

Max Cutting Depth: 20mm wood, 30mm black acrylic

Stainless Steel Engraving: Yes

Cutting Speed: 3mm plywood - 300mm/min

Interface

12V: Power positive .

GND: Power ground or power negative.

TTL/PWM: TTL = PWM, input 3.3V~12V to turn on laser module, conect to GND to turn off laser module.

Temperature: do not connect, please ignore.

Connect 12V and GND pin to 12V power, ensure the power adapter is sufficient, 5A is recommended.

Connect TTL/PWM pin to your control board PWM output pin.

Test Board

Maintenance

Although this module adopts internal air-assisted design, long-term use may not prevent dust or a small amount of smoke from affecting the lens. It is recommended to clean the lens with a clean cotton swab. Dust or smoke may overheat the lens and cause the lens to burn out. Re-acquire the lens Will delay your use.

FAQs

Inferior power supply leads to the problem of laser power drop!

About PWM signal specification.

How to distinguish my laser module types ?

How to make laser module work with your control board ?

How to check my cable connection is properly

For more information, please search in NEJE Document