Table of Contents

Install

Install the module height adjuster on the z-axis, and adjust the module height and focus by adjusting the M5 Allen key to slide the module up and down.

Attention

Please do not leave the equipment when the equipment is working, long-term stay may cause the material to burn!

Please wear protective glasses before operation!

Please do not touch the laser outlet with your hands. It may burn your hands!

Please avoid strongly impact on the machine!

Children under 14 years of age are prohibited from using this product!

Children over 14 years of age need adult supervision when using this product!

Avoid accidental touch by pets!

Adjust Focus

E40 is a high-power (pulse output power 12W, continuous work greater than 10W) fixed-focus module. The most prominent optical features of E40 are extremely small focus energy density and XY symmetry, especially in nested cutting and fine drawing of materials less than 4mm. Shockingly, it can cut 0.05mm stainless steel sheet. It has a unique ability in engraving applications. Of course, it can cut materials less than 12mm thick, but in the application of materials less than 4mm, it is the king.

How to quickly find focus by observing low light?

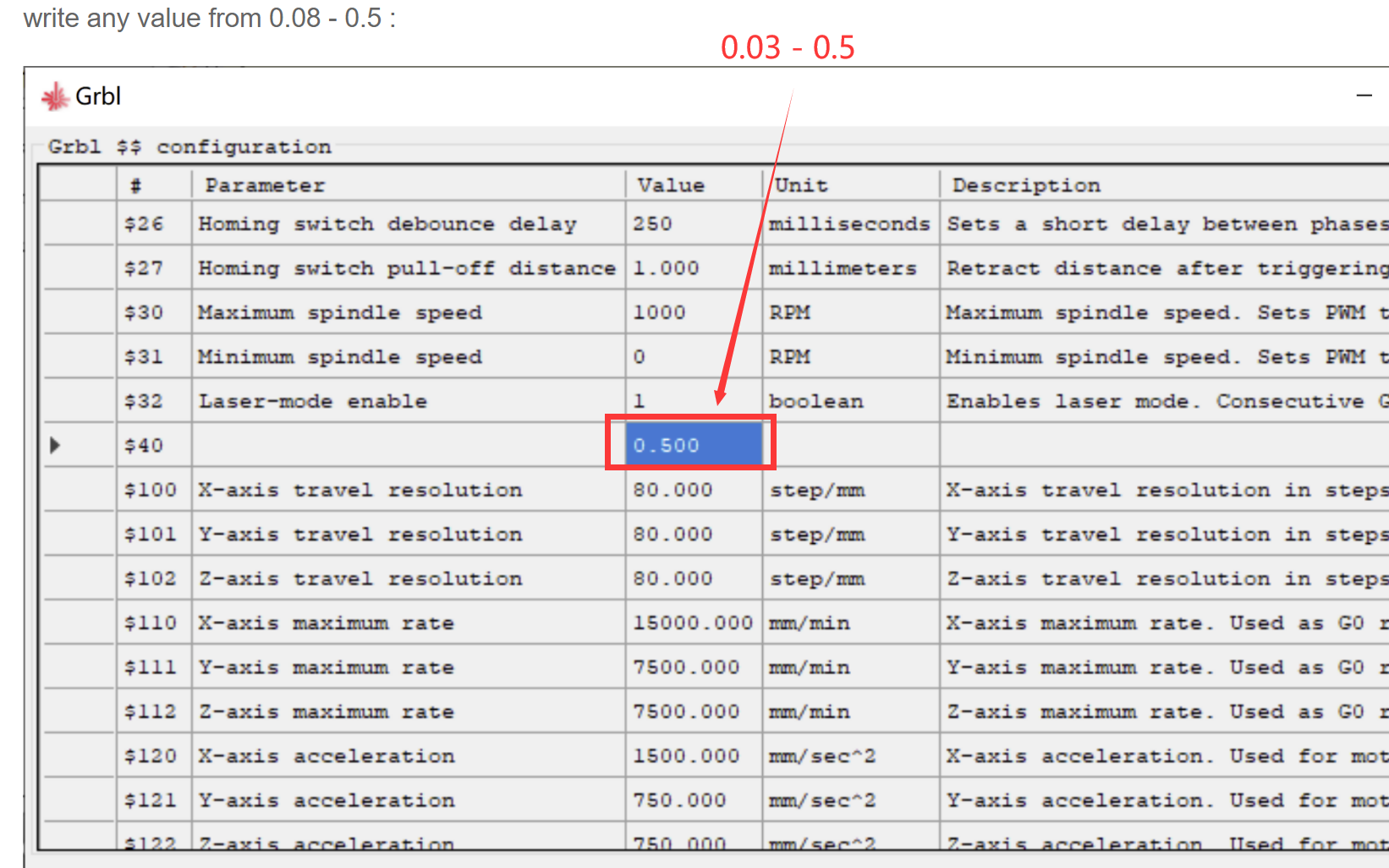

1. Adjust the suitable low light through the software. The NEJE mode can be adjusted in the “Settings” column of the NEJE Win software; the GRBL mode can be adjusted in the “Grbl Configuration” of the laserGRBL software, which has been explained above.

2.Put a gray cardboard on the surface of the white material (such as plywood) as a focus reference to find the precise focus. A fine focal point can be observed through the protective goggles or the shade of the module.

Laser & Material Database

Max Cutting depth < 12mm

Gap: 0.1mm

Typical Material Parameters:

Grey Paperboard Cutting 1mm

Focus on the surface. Speed (mm/min): 800 Max Power(%): 100 Air Assist: ON Number of Passes: 1

steel cutting 0.05mm

updating...

Mdf cutting 3mm

updating...

Acrylic cutting 3mm

updating...

plywood cutting 3mm

updating...

Leather cutting 3mm

updating...

Stainless steel carving

updating...

About air assist

NEJE E40 is equipped with 1 high-temperature-resistant (1000°C) protective lenses, which can be replaced. Pay attention to regularly clean the surface oil and foreign matter according to the actual situation of use. Oil and foreign matter sticking to the surface may cause high temperature to soften the lens.

When cutting mdf, leather and high-density materials, it is necessary to add air assistance with a pressure of not less than 30psi.

The air nozzle must be aligned with the cutting port to blow off the carbonized material, otherwise it will be ineffective.

When do you need air assist

Air-assisted engraving or cutting can only be used for engraving or cutting that produces more carbonized substances. Generally, the depth of engraving is less than 1mm, and the cutting of plywood less than 2mm does not require air assist. A small fan can be used to blow off the smoke generated by the engraving. Air assist is not recommended when engraving images, and adding air assist at this time will destroy image details.

What kind of air pump is suitable for cutting

The main meaning of air assist is to blow off the carbonized material produced by cutting, and the general oxygener and electromagnetic inflator have almost no meaning. only the pressure of the oil pump and air compressor (0.4-1.5mPa) has the effect of blowing away the carbonized material. but it should be noted that the air of the oil pump contains oil and cannot be directly used for the air-assisted module of the closed cavity, otherwise the oil will contaminate the lens, resulting in power drop or damage to the lens. The air pressure of the air compressor can be used for a short time with the closed cavity, but When used for a long time, the water-containing gas will contaminate the lens, cause the power to drop, and even damage the lens.

Specification

Radiator Size: 40.5 x 56 x 113 mm Weight: 300g Interface: PH2.0 4Pin + 2Pin(EX Power) Drive Design: Built-in Input: 12V 2A + Optical Power: < 12W Wavelength: 450nm Laser Class: Class 4 Number of Diodes: 4 PWM Input: VPP(3.3-24V), Recomend 1KHz Max Speed of the Fan: 10600RPM(Double ball bearing) Quiet Design: (Dynamic adjustment)Drive the built-in control ic, judge the working state and adjust the fan work. ESD Design: Yes Temperature feedback:Yes Recommend Cutting & Carving Depth: <4mm (The data is tested by NEJE users, and it needs to be done under more accurate focusing and adding correct and certain strength of air assist.) Max Cutting Depth: 12mm Stainless Steel Carving: Yes 0.1mm Stainless Steel Cutting: Yes

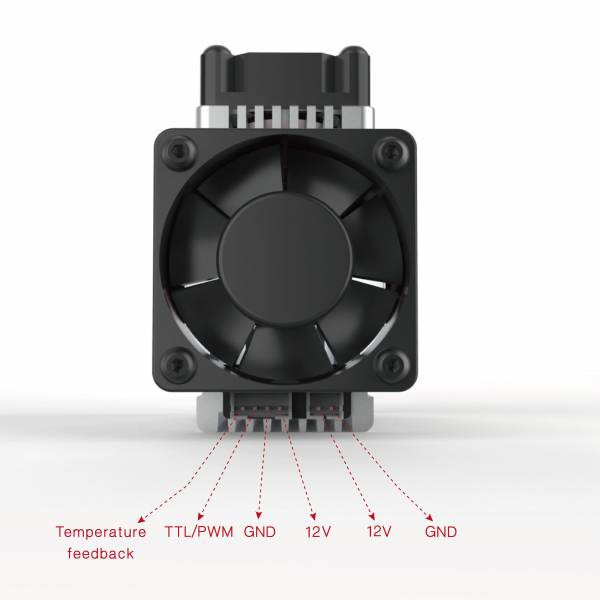

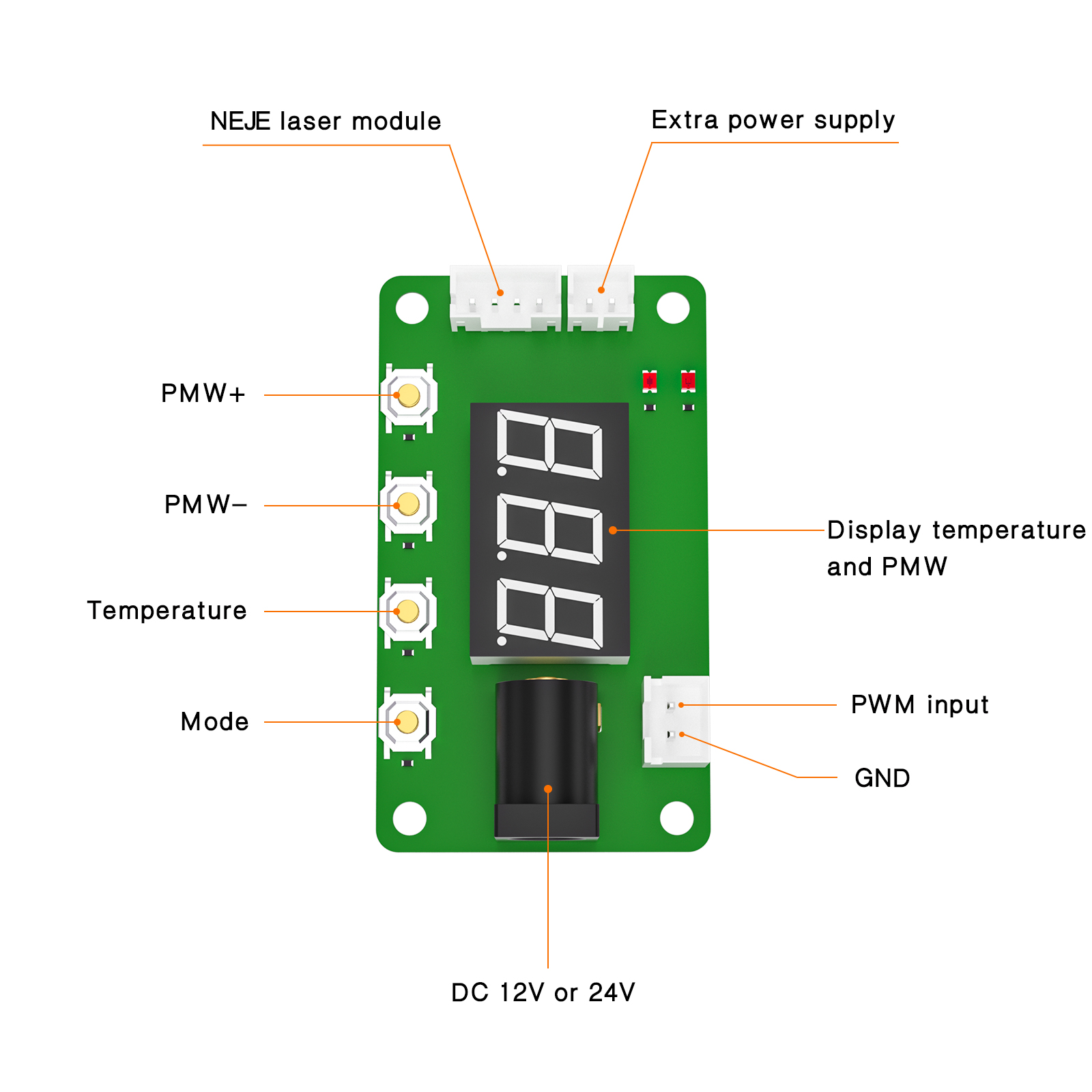

Interface

12V: Power positive .

GND: Power ground or power negative.

TTL/PWM: TTL = PWM, input 3.3V~12V to turn on laser module, conect to GND to turn off laser module.

Temperature: do not connect, please ignore.

Connect 12V and GND pin to 12V power, ensure the power adapter is sufficient, >3A is recommended.

Connect TTL/PWM pin to your control board PWM output pin.

FAQs

Inferior power supply leads to the problem of laser power drop!

About PWM signal specification.

How to distinguish my laser module types ?

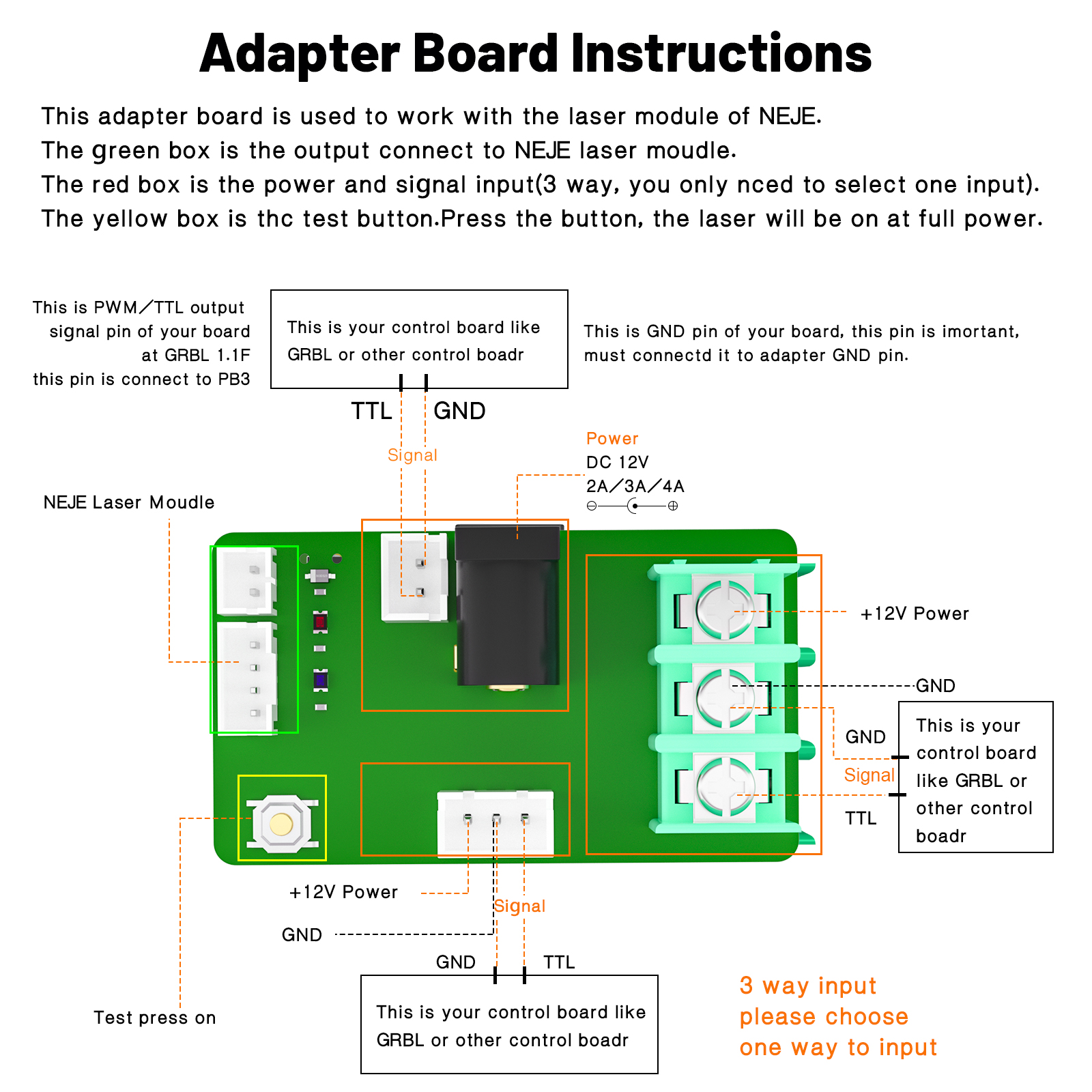

How to make laser module work with your control board ?

How to check my cable connection is properly

For more information, please search in NEJE Document

Control Board

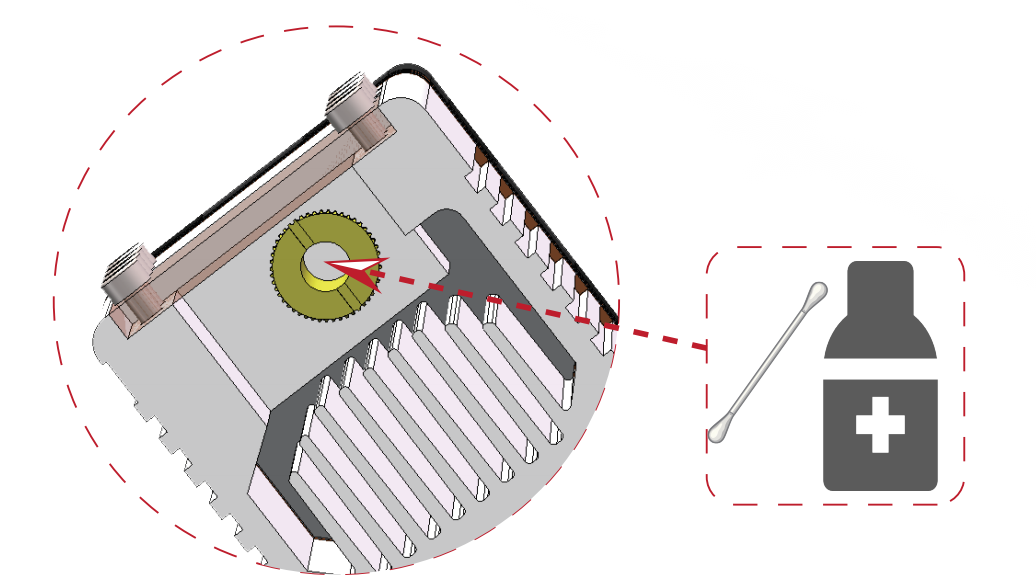

Maintenance

Although this module adopts internal air-assisted design, long-term use may not prevent dust or a small amount of smoke from affecting the lens. It is recommended to clean the lens with a clean cotton swab. Dust or smoke may overheat the lens and cause the lens to burn out. Re-acquire the lens Will delay your use.