Table of Contents

E80 is a really strong performance, high efficiency, reliable and easy to maintain, engraving and cutting performance are very strong high-performance module, E80 module internal use of a unique matrix optical module, top Nichia high-performance diodes, and high-efficiency copper fan thermal module design, the module by NEJE top optical engineers design and training of professional workers to produce, high-performance and longevity is the module's biggest feature, its performance is reflected in its head design has a smaller focus and angle compared to other similar modules, so it has no less than 40W module with a smaller cutting volume. Features, its performance is reflected in its head design relative to other similar modules with a smaller focus and angle, in cutting materials with a smaller amount of cutting, so it has no less than 40W module productivity, and has a more detailed and comprehensive carving effect and cutting edge is very rare to provide productivity and productivity of the high-performance module.

Features

The power output has fast dynamic response, accurate and stable power delivery, and precise reproduction of designs in engraving and cutting.

Equipped with three types of protective heads, it ensures cleaner edges when cutting materials of different thicknesses while being convenient for maintenance.

Maintenance is convenient, and the NEJE's specially designed lens protector, rated for 1600°C and featuring a special coating for 450nm wavelength windows, includes a double fan design that is easy to replace.

The top-notch Nichia collimated light source has a power 10% higher than that of similar products and an average lifespan 40% longer.

With the sophisticated lens processing technology, it features a smaller focal point, enabling more delicate engraving and finer cutting.

It ensures uniform symmetrical cutting in both X and Y depth of field.

The red copper heat dissipation system combined with double ball bearings allows it to operate continuously at 100% power.

The built-in intelligent program in the driver can dynamically recognize the working status and adjust the fan speed to effectively control the noise.

The multi-nozzle design makes it suitable for various material thicknesses.

Equipped with temperature feedback and super electrostatic protection technology, it comes with free after-sales service for two years with global warehouse shipping.

Application Examples

Wood Engraving

https://www.facebook.com/photo/?fbid=122159047838152033&set=gm.3764966033748445&idorvanity=2737185006526558

Outstanding 3D Stereoscopic Grayscale and Cutting Comprehensive Performance.

https://www.facebook.com/photo/?fbid=122159047838152033&set=gm.3764966033748445&idorvanity=2737185006526558

Outstanding 3D Stereoscopic Grayscale and Cutting Comprehensive Performance.

https://www.facebook.com/photo?fbid=8307583319348729&set=pcb.3811897305721984

3D Engraving Bamboo Cutting Board

10000/90%/2 passes/1mm offset

NEJE Max4 & E80

https://www.facebook.com/photo?fbid=8307583319348729&set=pcb.3811897305721984

3D Engraving Bamboo Cutting Board

10000/90%/2 passes/1mm offset

NEJE Max4 & E80

https://www.facebook.com/photo/?fbid=10163087879061323&set=gm.3856961521215562&idorvanity=2737185006526558

E80,deep engraving

https://www.facebook.com/photo/?fbid=10163087879061323&set=gm.3856961521215562&idorvanity=2737185006526558

E80,deep engraving

https://www.facebook.com/photo/?fbid=10160694982742832&set=gm.3740125469565835&idorvanity=2737185006526558

Major work done, undertaken with a NEJE Max4, E80 module. Thanks for this great laser engraver!

https://www.facebook.com/photo/?fbid=10160694982742832&set=gm.3740125469565835&idorvanity=2737185006526558

Major work done, undertaken with a NEJE Max4, E80 module. Thanks for this great laser engraver!

https://www.facebook.com/photo/?fbid=7672485926134417&set=gm.3755708634674185&idorvanity=2737185006526558

tu moja praca na e80 laser.takie male 3d wypalone.

https://www.facebook.com/photo/?fbid=7672485926134417&set=gm.3755708634674185&idorvanity=2737185006526558

tu moja praca na e80 laser.takie male 3d wypalone.

https://www.facebook.com/photo/?fbid=9530944043586922&set=pcb.3856245107953870

For grandma's eightieth birthday. Glasses, for tablets, of course, 😉

https://www.facebook.com/photo/?fbid=9530944043586922&set=pcb.3856245107953870

For grandma's eightieth birthday. Glasses, for tablets, of course, 😉

Wood Cutting

Metal Engraving

https://www.facebook.com/photo/?fbid=8550790361643728&set=gm.3816394401938941&idorvanity=2737185006526558

Bookmark and Steel Tag

15000/80% 1000/90%

E80 20w

https://www.facebook.com/photo/?fbid=8550790361643728&set=gm.3816394401938941&idorvanity=2737185006526558

Bookmark and Steel Tag

15000/80% 1000/90%

E80 20w

Stainless Steel Engraving and Cutting

Photo Engraving

https://www.facebook.com/photo/?fbid=122117823314420484&set=pcb.3856638744581173

Did a few coasters to suit this time of year 🥶 love them 💚

Bing AI images

Neje Max 4 E80

Speed 9000

Power 12

212 dpi

Greyscale on Lightburn

https://www.facebook.com/photo/?fbid=122117823314420484&set=pcb.3856638744581173

Did a few coasters to suit this time of year 🥶 love them 💚

Bing AI images

Neje Max 4 E80

Speed 9000

Power 12

212 dpi

Greyscale on Lightburn

https://www.facebook.com/photo/?fbid=10230120163221001&set=gm.3732883396956709&idorvanity=2737185006526558

Pierwsza próba z delikatnym kolorem.E80 6000/20% 423 dpi Biały MDF ,kolory żółty, pomarańczowy,zielony,niebieski

https://www.facebook.com/photo/?fbid=10230120163221001&set=gm.3732883396956709&idorvanity=2737185006526558

Pierwsza próba z delikatnym kolorem.E80 6000/20% 423 dpi Biały MDF ,kolory żółty, pomarańczowy,zielony,niebieski

https://www.facebook.com/photo/?fbid=10231177280085676&set=gm.3708840802694302&idorvanity=2737185006526558

Max4 E80 + AI and ME 🥰

https://www.facebook.com/photo/?fbid=10231177280085676&set=gm.3708840802694302&idorvanity=2737185006526558

Max4 E80 + AI and ME 🥰

From Pavan Kumar

New work 😁.Same method as last one. You can engrave 3rd image directly.

Machine: NEJE Max4 E80

Image: imagr invert, adjust DPI to 318

Material: MDF. spray 2 layers of white, 2 layers of black, one layer dries before spraying the next layer.

Parameter: lightburn, 15000mm/min, 50%, air assist off,line space 0.1mm,Jarvis

From Pavan Kumar

New work 😁.Same method as last one. You can engrave 3rd image directly.

Machine: NEJE Max4 E80

Image: imagr invert, adjust DPI to 318

Material: MDF. spray 2 layers of white, 2 layers of black, one layer dries before spraying the next layer.

Parameter: lightburn, 15000mm/min, 50%, air assist off,line space 0.1mm,Jarvis

https://www.facebook.com/photo/?fbid=8522892717766826&set=pcb.3813345482243833

Denim Bag, 20000/13%, E80

https://www.facebook.com/photo/?fbid=8330152736996877&set=gm.3731457593765956&idorvanity=2737185006526558

Just testing! A pice of stone! Zäppo is the name of my dog! 35mm/min 95%

https://www.facebook.com/photo/?fbid=8330152736996877&set=gm.3731457593765956&idorvanity=2737185006526558

Just testing! A pice of stone! Zäppo is the name of my dog! 35mm/min 95%

With the help of black cardboard, you can engrave on transparent acrylic. 15000mm/min, 50%power NEJE Max 4 & E80

from Alexis Phipps

Dragon Year

3mm red acrylic

NEJE MAX 4 & E80

5000mm/min, 80%power for engraving and 350mm/min, 80%power for cutting

from Alexis Phipps

Dragon Year

3mm red acrylic

NEJE MAX 4 & E80

5000mm/min, 80%power for engraving and 350mm/min, 80%power for cutting

from Alexis Phipps

Neje Max 4 & E80

8000mm/min, 80%power, grayscale

from Alexis Phipps

Neje Max 4 & E80

8000mm/min, 80%power, grayscale

40*60cm Coir Doormat Engraving!

12000mm/min, 60%power, no air assist, NEJE E80

40*60cm Coir Doormat Engraving!

12000mm/min, 60%power, no air assist, NEJE E80

https://www.facebook.com/photo?fbid=8610188739088184&set=pcb.3855398111371903

Ceramic plate😋

Titanium oxide powder & Alcohol spray

Tutorial:https://drive.google.com/file/d/1jp6nOmF90H92OntYOLvVQOioY-B3nZ3X/view?usp=sharing

https://www.facebook.com/photo?fbid=8610188739088184&set=pcb.3855398111371903

Ceramic plate😋

Titanium oxide powder & Alcohol spray

Tutorial:https://drive.google.com/file/d/1jp6nOmF90H92OntYOLvVQOioY-B3nZ3X/view?usp=sharing

Engraving with Z axsis

About air assist

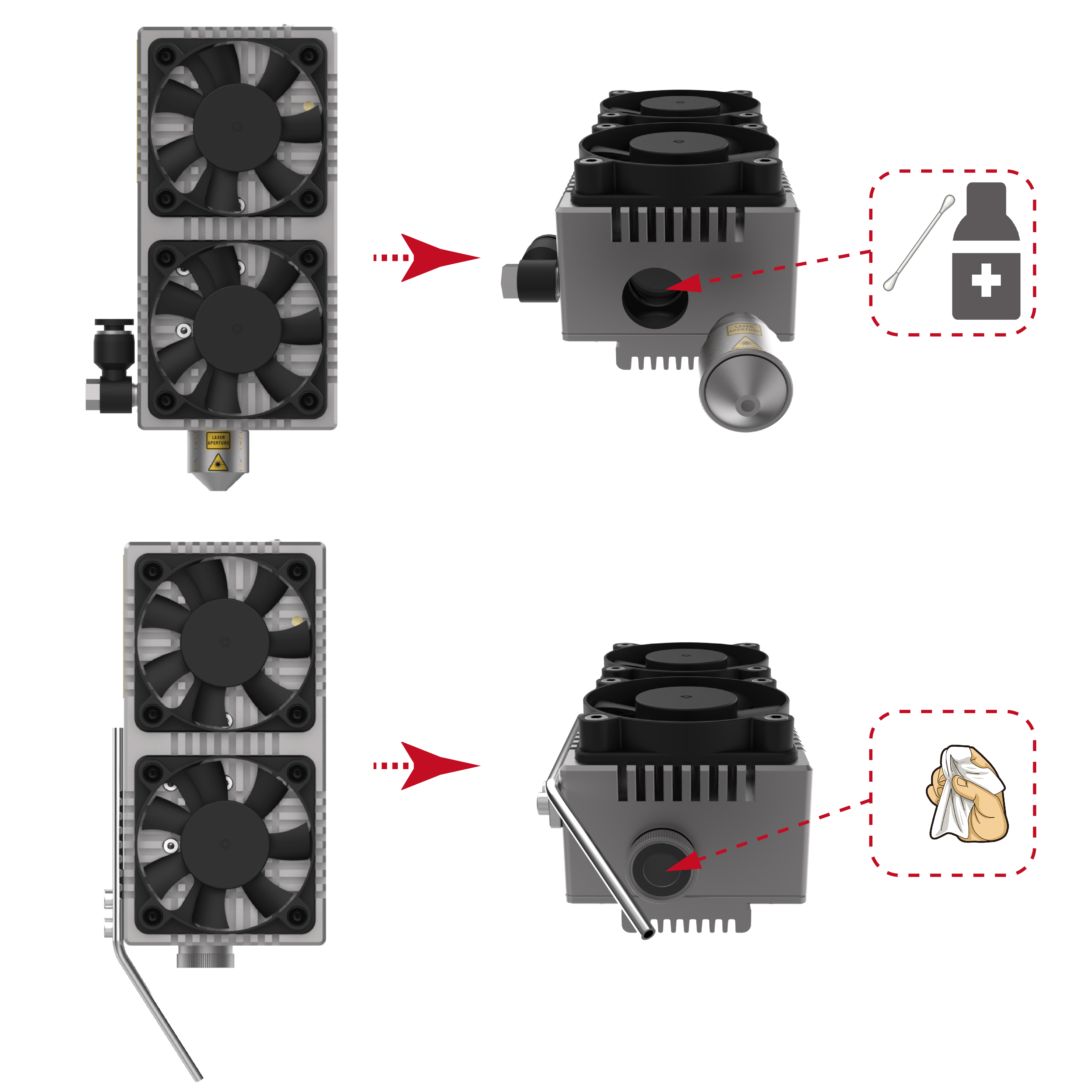

NEJE E80 is equipped with 2 high-temperature-resistant (1000°C) protective lenses, which can be replaced. Pay attention to regularly clean the surface oil and foreign matter according to the actual situation of use. Oil and foreign matter sticking to the surface may cause high temperature to soften the lens.

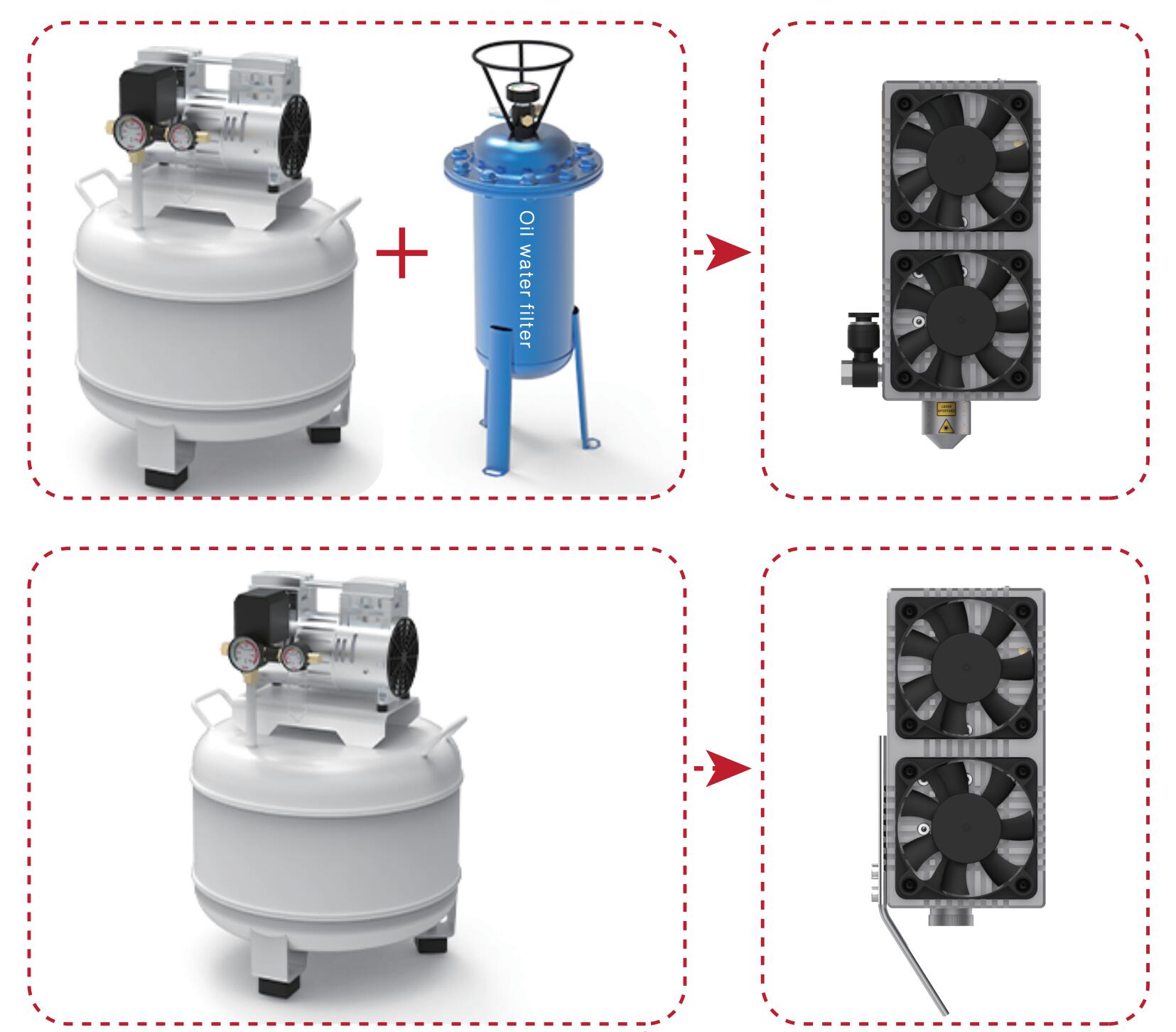

NEJE E80 can use 2 types of air assist. a. Conical air nozzle in the inner cavity, this method needs to use oil-free and water-free air source, (Note: ordinary oil-water filters can only filter simply, not completely, and need to be cleaned regularly built-in protective lens) b. Stainless steel pipe air nozzle, this method can use oily water air source, easy maintenance, and can quickly clean the lens, the metal pipe needs to be aligned with the focus.

When cutting mdf, leather and high-density materials, it is necessary to add air assistance with a pressure of not less than 30psi.

The air nozzle must be aligned with the cutting port to blow off the carbonized material, otherwise it will be ineffective.

When do you need air assist?

Air-assisted engraving or cutting can only be used for engraving or cutting that produces more carbonized substances. Generally, the depth of engraving is less than 1mm, and the cutting of plywood less than 2mm does not require air assist. A small fan can be used to blow off the smoke generated by the engraving. Air assist is not recommended when engraving images, and adding air assist at this time will destroy image details.

What kind of air pump is suitable for cutting

The main meaning of air assist is to blow off the carbonized material produced by cutting, and the general oxygener and electromagnetic inflator have almost no meaning. only the pressure of the oil pump and air compressor (0.4-1.5mPa) has the effect of blowing away the carbonized material. but it should be noted that the air of the oil pump contains oil and cannot be directly used for the air-assisted module of the closed cavity, otherwise the oil will contaminate the lens, resulting in power drop or damage to the lens. The air pressure of the air compressor can be used for a short time with the closed cavity, but When used for a long time, the water-containing gas will contaminate the lens, cause the power to drop, and even damage the lens.

Database

Max Cutting depth < 30mm

Typical Material Parameters:

E80 cutting test(video) :17 mm pinewood

17mm Pine Board With NEJE Max 4 Speed (mm/min): 300 Max Power(%): 100 Air Assist: ON Number of Passes: 3 (2.5) Z Offset (mm):(The distance between the module and the surface of the board)-Focal length(25mm) +4mm Z step per pass (mm): 1.5

Note: (Number of Passes - 1)*Z step per pass < 7mm (The standard air nozzle is designed for cutting less than 17mm. If you want to increase the cutting of materials larger than 17mm, you can increase the cutting thickness by replacing the plane protection head + metal air pipe.)

E80 cutting test(video) :10mm birch plywood

10mm BIRCH PLYWOOD With NEJE Max 4 Speed (mm/min): 500 Max Power(%): 100 Air Assist: ON Number of Passes: 2 Z Offset (mm): (The distance between the module and the surface of the board)-Focal length(25mm) Z step per pass (mm): 2

E80 cutting test(video) :3mm MDF board

3mm mdf board With NEJE Max 4 Speed (mm/min): 650 Max Power(%): 100 Air Assist: ON Number of Passes: 1 Z Offset (mm): (The distance between the module and the surface of the board)-Focal length(25mm)

Specification

Power density: 6666W/mm²

Focus size: 0.1×0.1mm

Radiator Size: 40.5 x 56 x 113 mm

Focus position: 25mm from the radiator (manufacturing error ±1mm)

Weight: 600g

Interface: PH2.0 4Pin + 2Pin(EX Power)

Drive Design: Built-in

Input: 24V 3A +

Optical Power: 24W

Wavelength: 450nm

Laser Class: Class 4

Number of Diodes: 4

PWM Input: VPP(3.3-24V), Recomend 1KHz

Max Speed of the Fan: 10600RPM(Double ball bearing)

Quiet Design: (Dynamic adjustment)Drive the built-in control ic, judge the working state and adjust the fan work.

ESD Design: Yes

Temperature feedback:Yes

Recommend Cutting & Carving Depth: <16mm (The data is tested by NEJE users, and it needs to be done under more accurate focusing and adding correct and certain strength of air assist.)

Stainless Steel Carving: Yes

0.15mm Stainless Steel Cutting: Yes

Interface

24V: Power positive .

GND: Power ground or power negative.

TTL/PWM: TTL = PWM, input 3.3V~24V to turn on laser module, conect to GND to turn off laser module.

Temperature: do not connect, please ignore.

Connect 24V and GND pin to 24V power, ensure the power adapter is sufficient, 3A-5A is recommended.

Connect TTL/PWM pin to your control board PWM output pin.

E80 driver has very high conversion efficiency, input 65W can output 24W optical power.

Test Board

Compatibility

Compatible with NEJE 3 Max (the motherboard model is higher than V1.1), only need to update the 24V power supply, the relay and valve control module are compatible, the temperature will be higher than in 12V mode, and there is no problem with indirect use. It is recommended to connect other devices through the control board, and it is recommended to use the device with Z-axis control, which is conducive to the full performance of the E80.

Maintenance

Although this module adopts internal air-assisted design, long-term use may not prevent dust or a small amount of smoke from affecting the lens. It is recommended to clean the lens with a clean cotton swab. Dust or smoke may overheat the lens and cause the lens to burn out. Re-acquire the lens Will delay your use.

FAQs

Inferior power supply leads to the problem of laser power drop!

About PWM signal specification.

How to distinguish my laser module types ?

How to make laser module work with your control board ?

How to check my cable connection is properly

For more information, please search in NEJE Document