Table of Contents

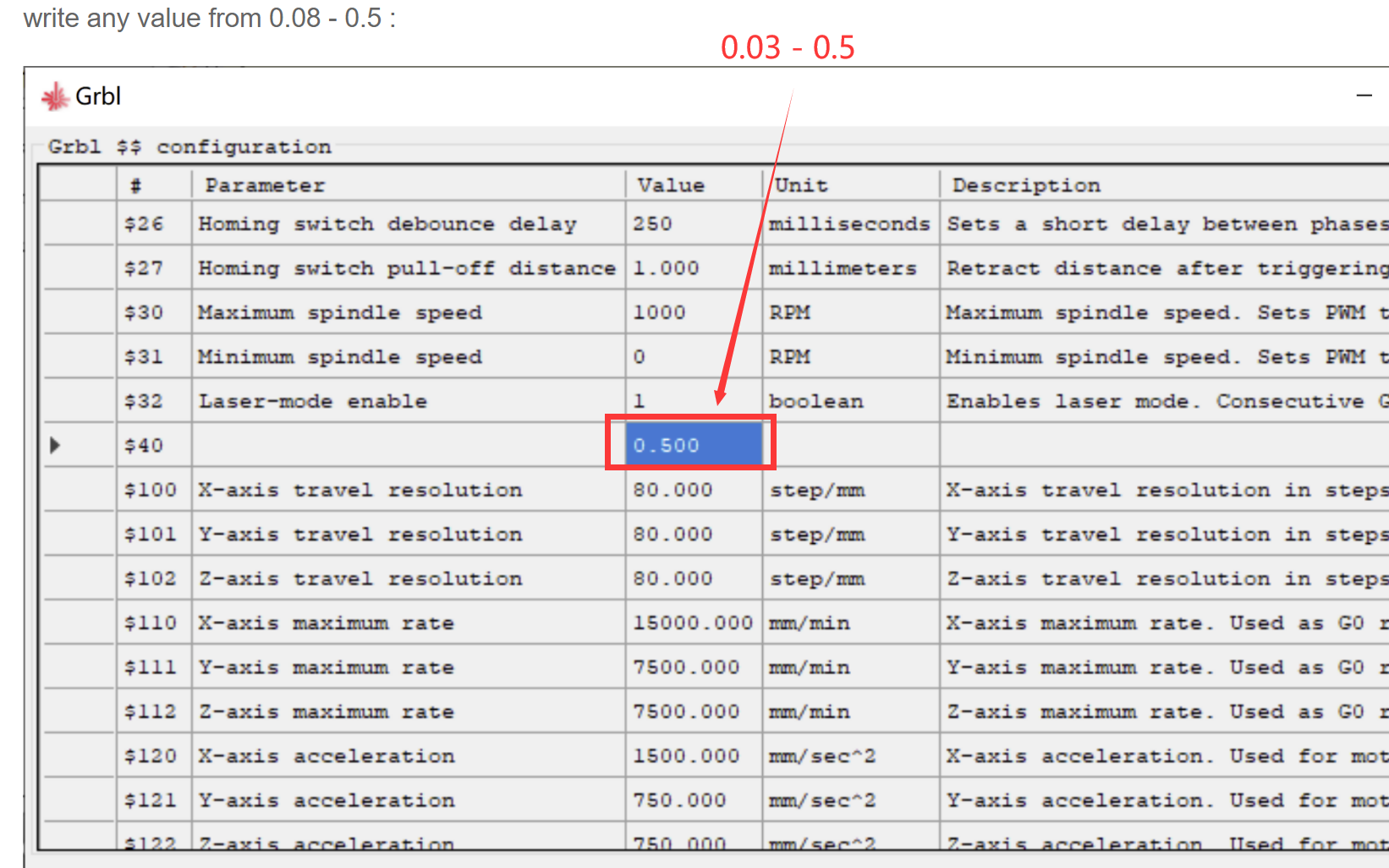

NEJE win software provides automatic low light. If you use laserGRBL and lightburn software to adjust the focus, you need to enter a command: M3 S1; and give a motion command, for example: G0 x10 y10 f1000; so that low light can be lit; The new NEJE 3 series has added low light adjustment in the GRBL firmware, which can turn on low light without inputting a command.

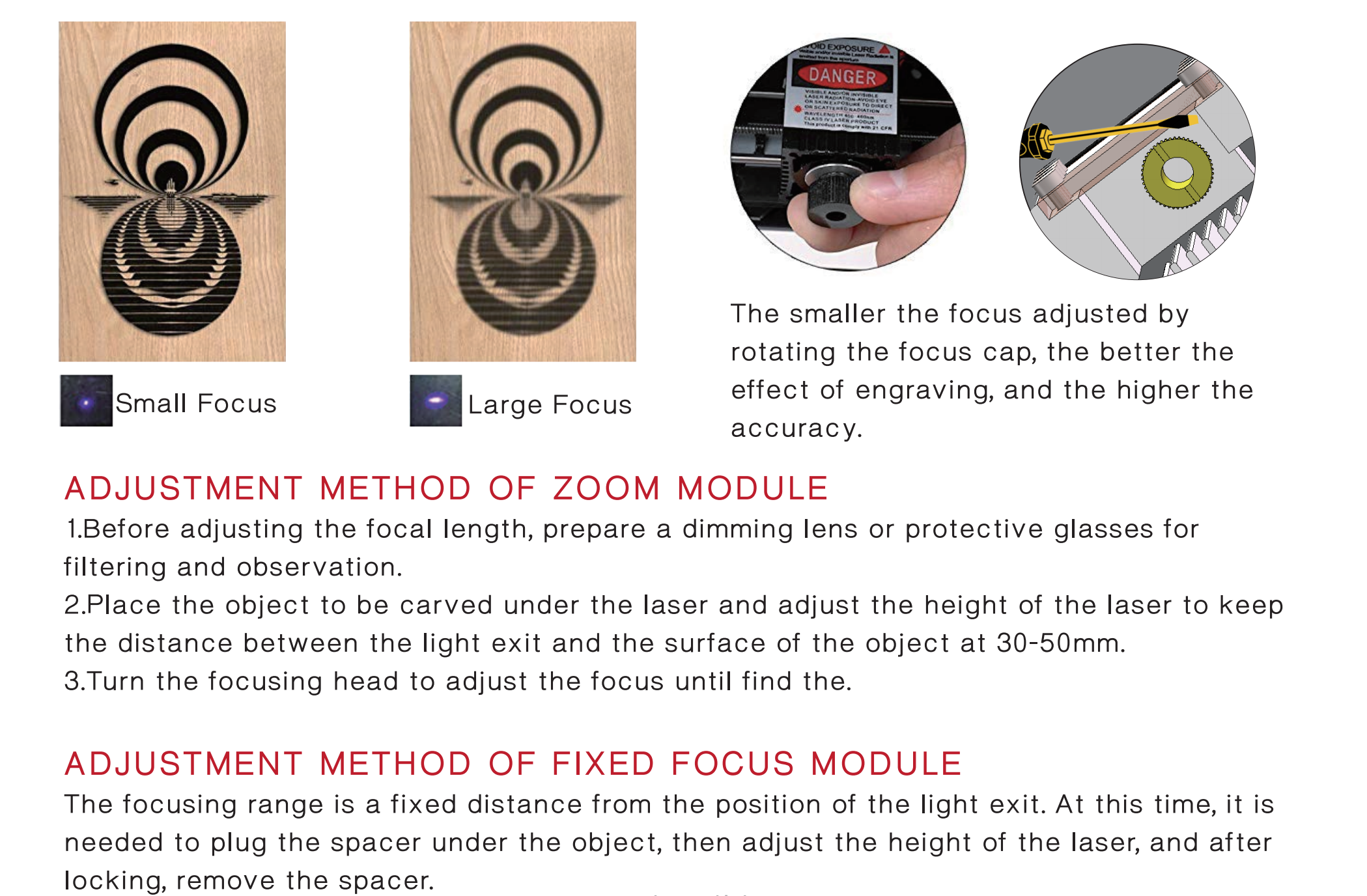

Understand the principle of focusing: if you use it for engraving, you can focus on the surface of the object. If you use it for cutting, you need to focus on the upper middle of the material.

A40640

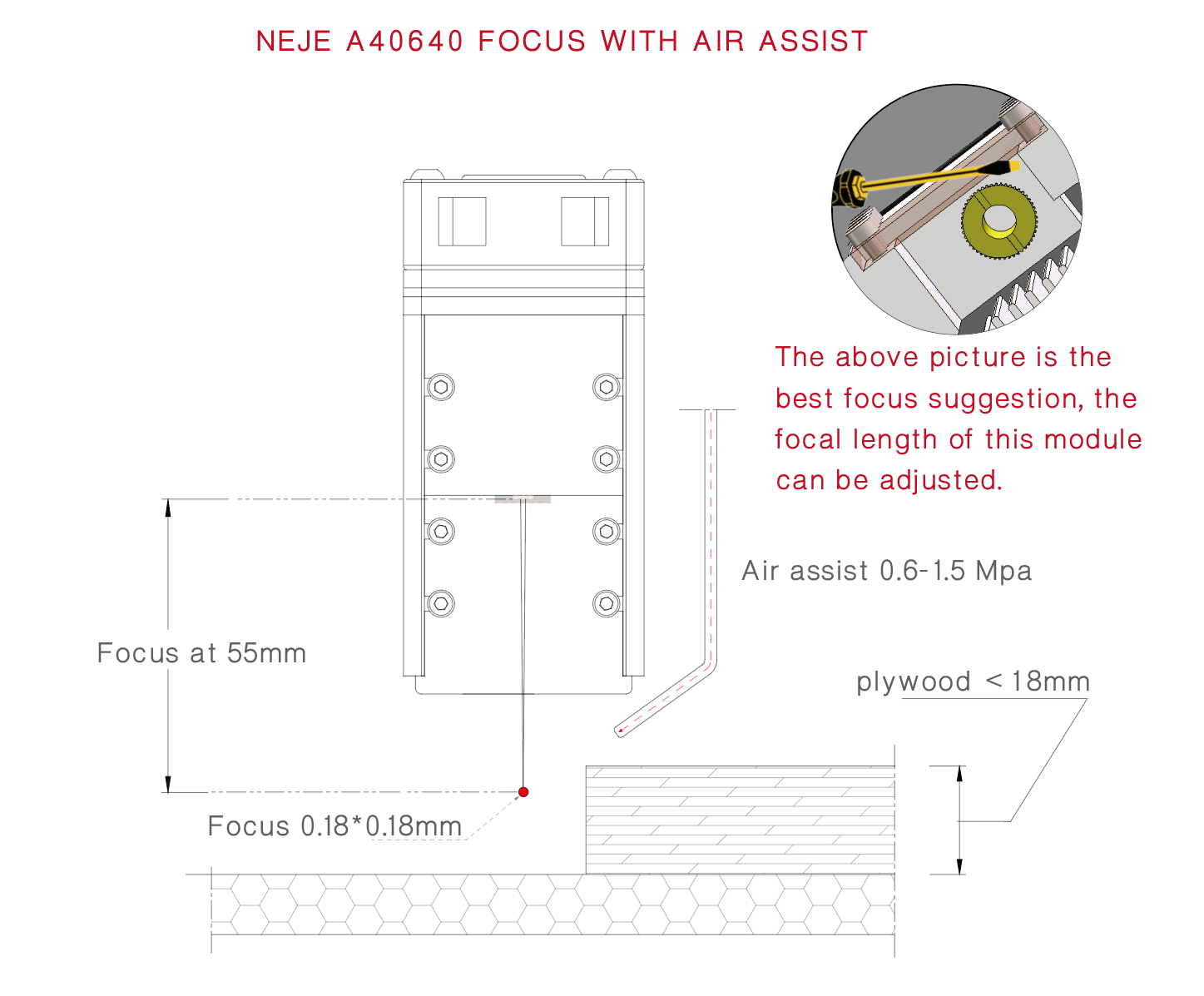

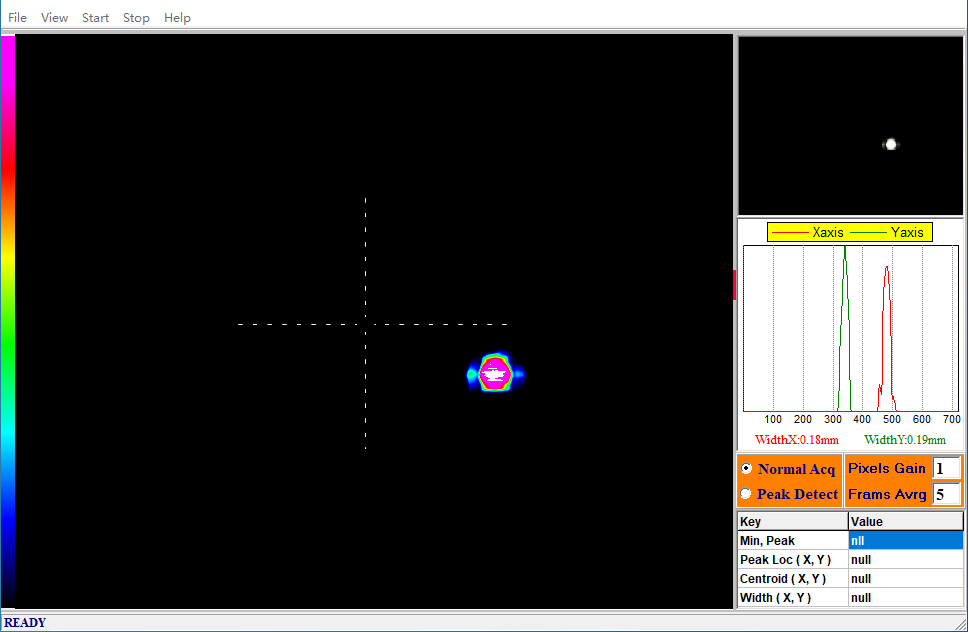

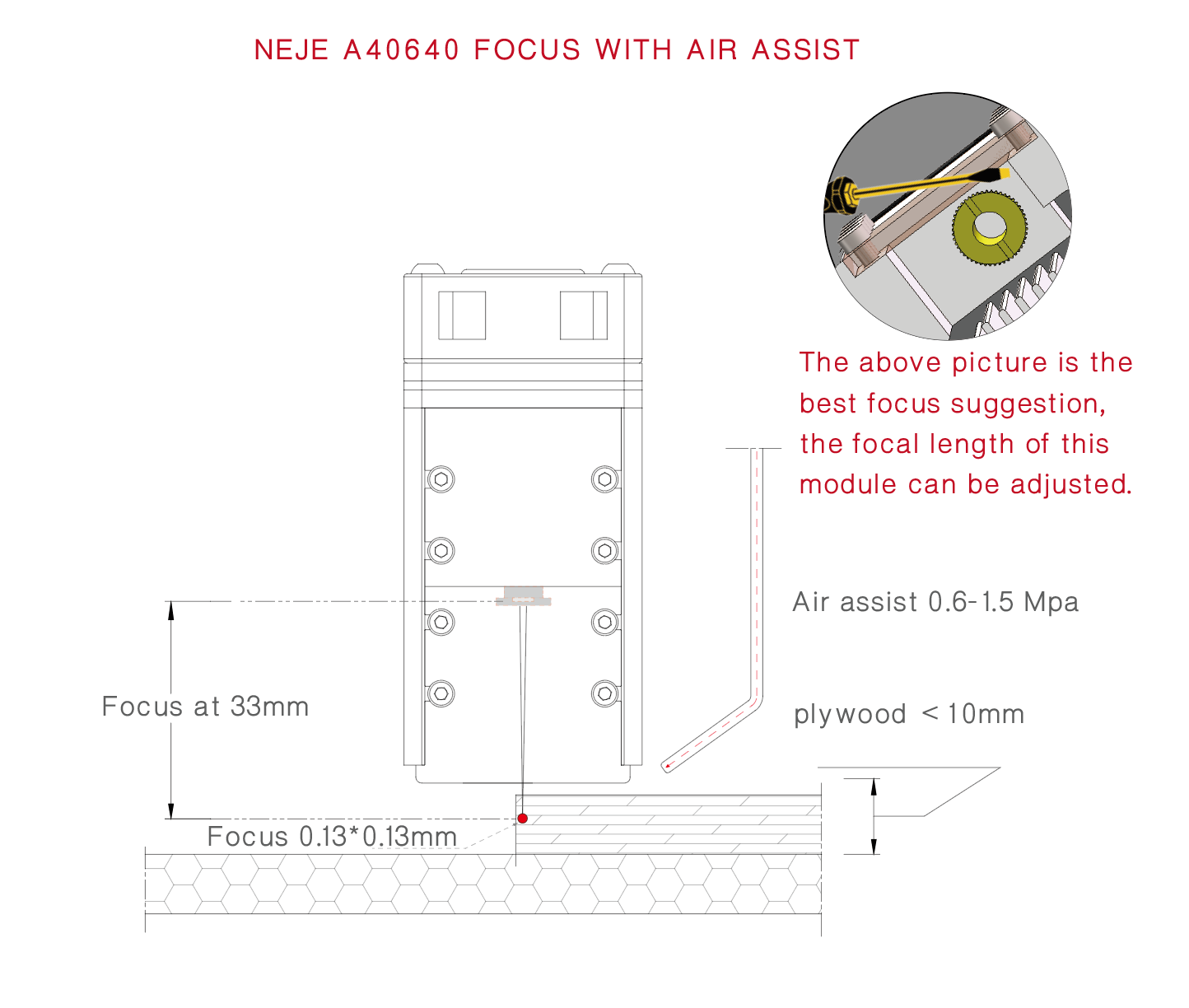

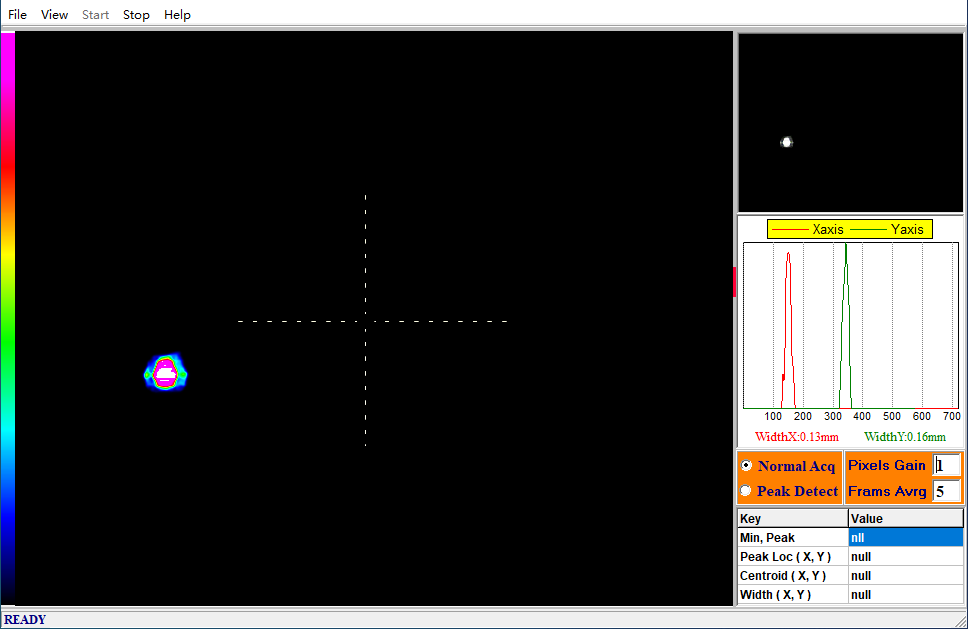

The A40640 is an adjustable focus module. Guide image above is a guide for the best adjustment settings. You can use a flat-blade screwdriver to adjust the focus position. Proper focus selection is a critical factor for cutting. You may need to try more few times. In addition, adding air assist will enhance cutting and engraving results, resulting in cleaner edges and enhanced cutting thickness and cutting efficiency.

Module: A40640, When focusing to 55mm position (lens-to-focus distance), you can get a 0.18×0.18mm focal point and be able to cut material up to 18-20mm (requires accurate focus, 0.6-1.5mpa air assist to align the cut).

When the focus is adjusted to about 33mm from the light outlet with a flat-blade screwdriver, you can get a focus of 0.13*0.13mm, which is suitable for engraving and fast cutting of materials smaller than 10mm.

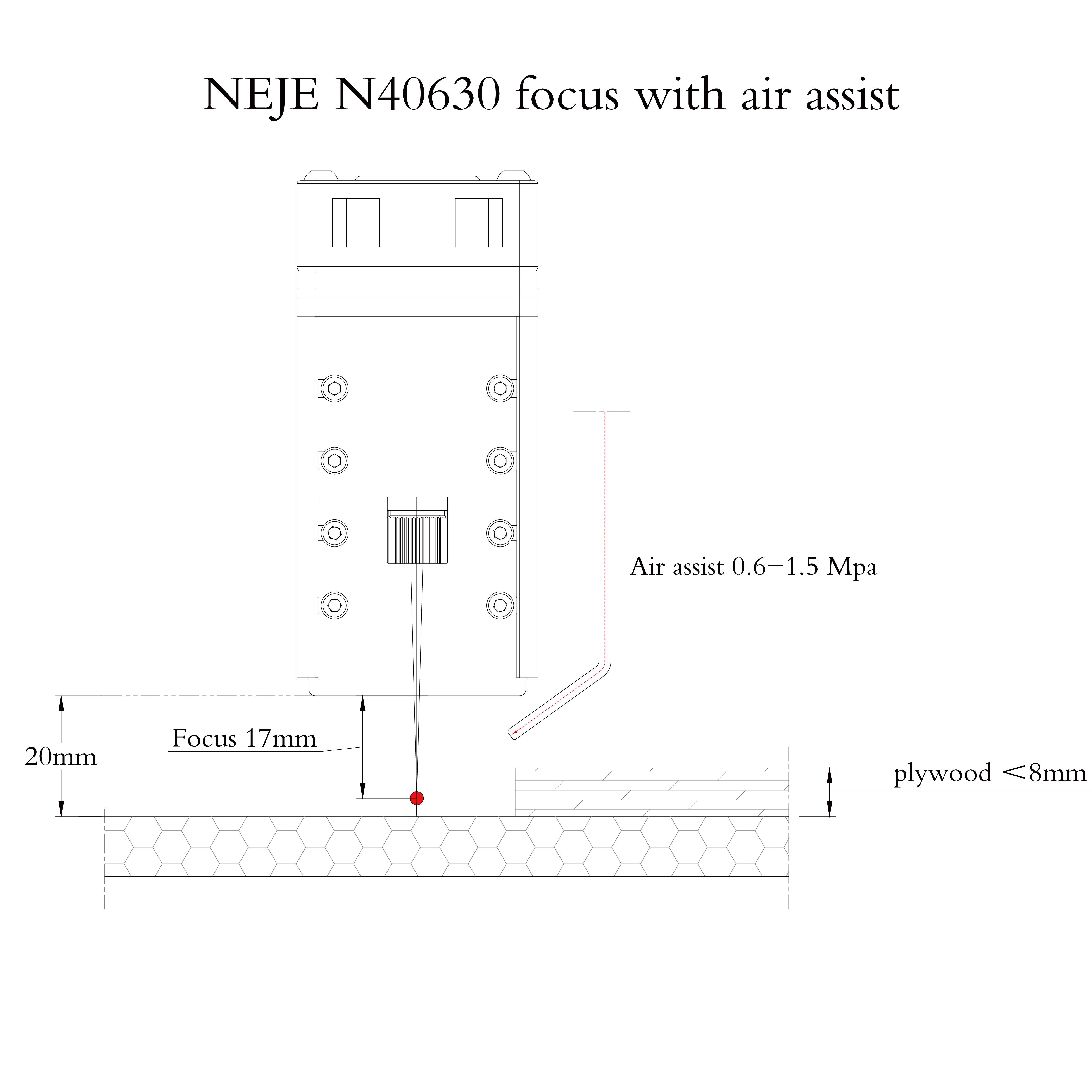

N40630

N40630 module: If it is mainly used for engraving, adjust the focus to a distance of 5mm below the light barrier; then slide the laser through a 5mm spacer to use a fixed focus method;

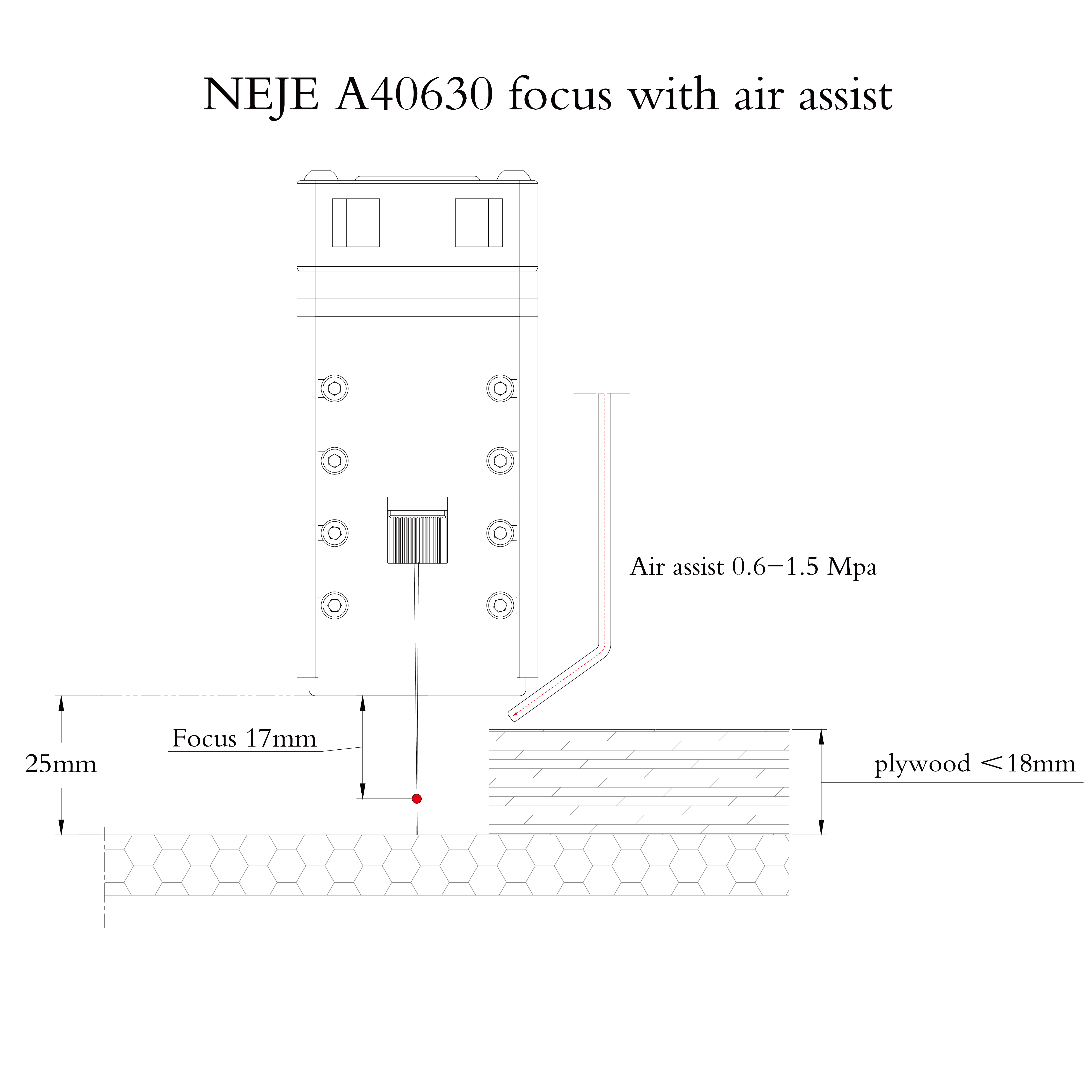

A40630

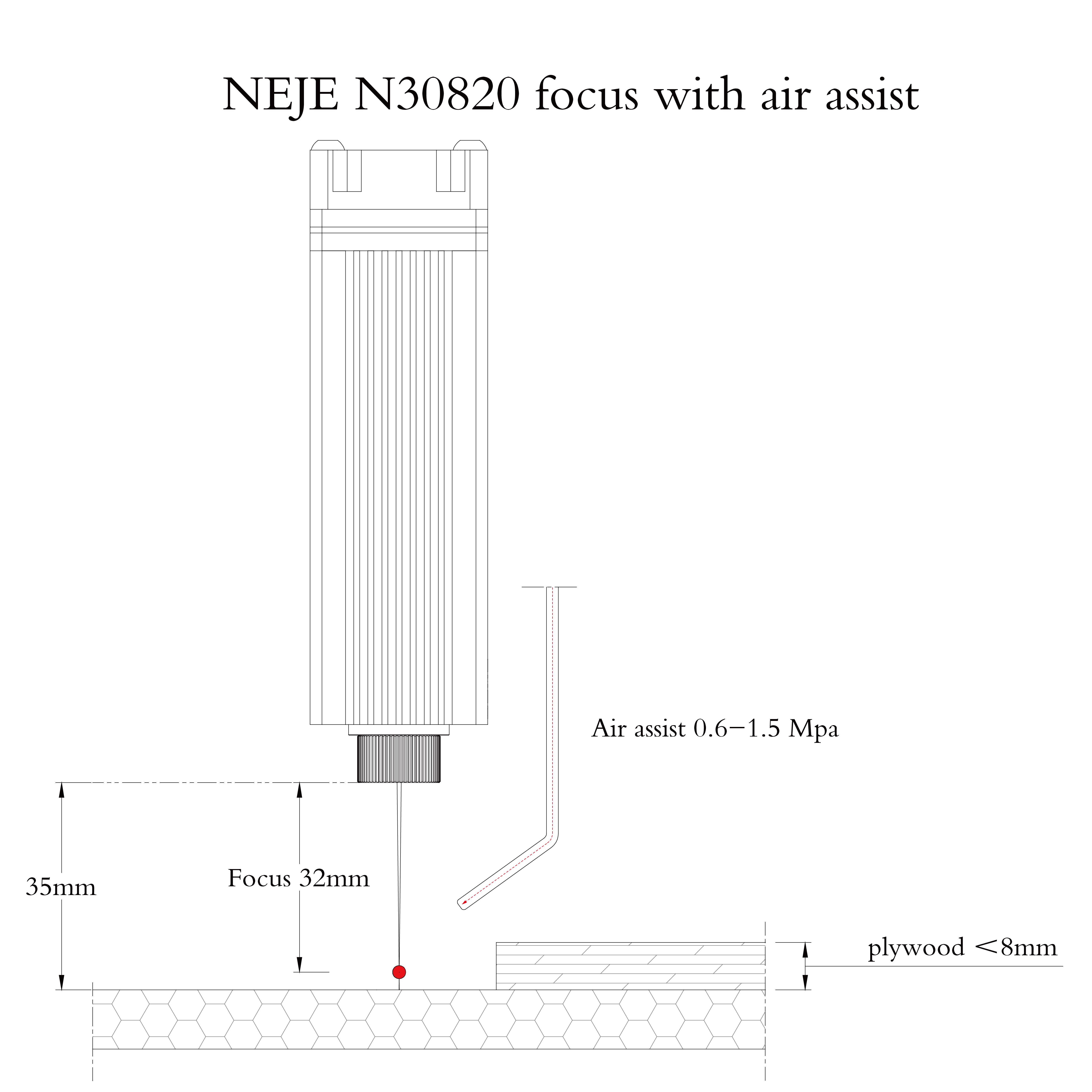

N30820

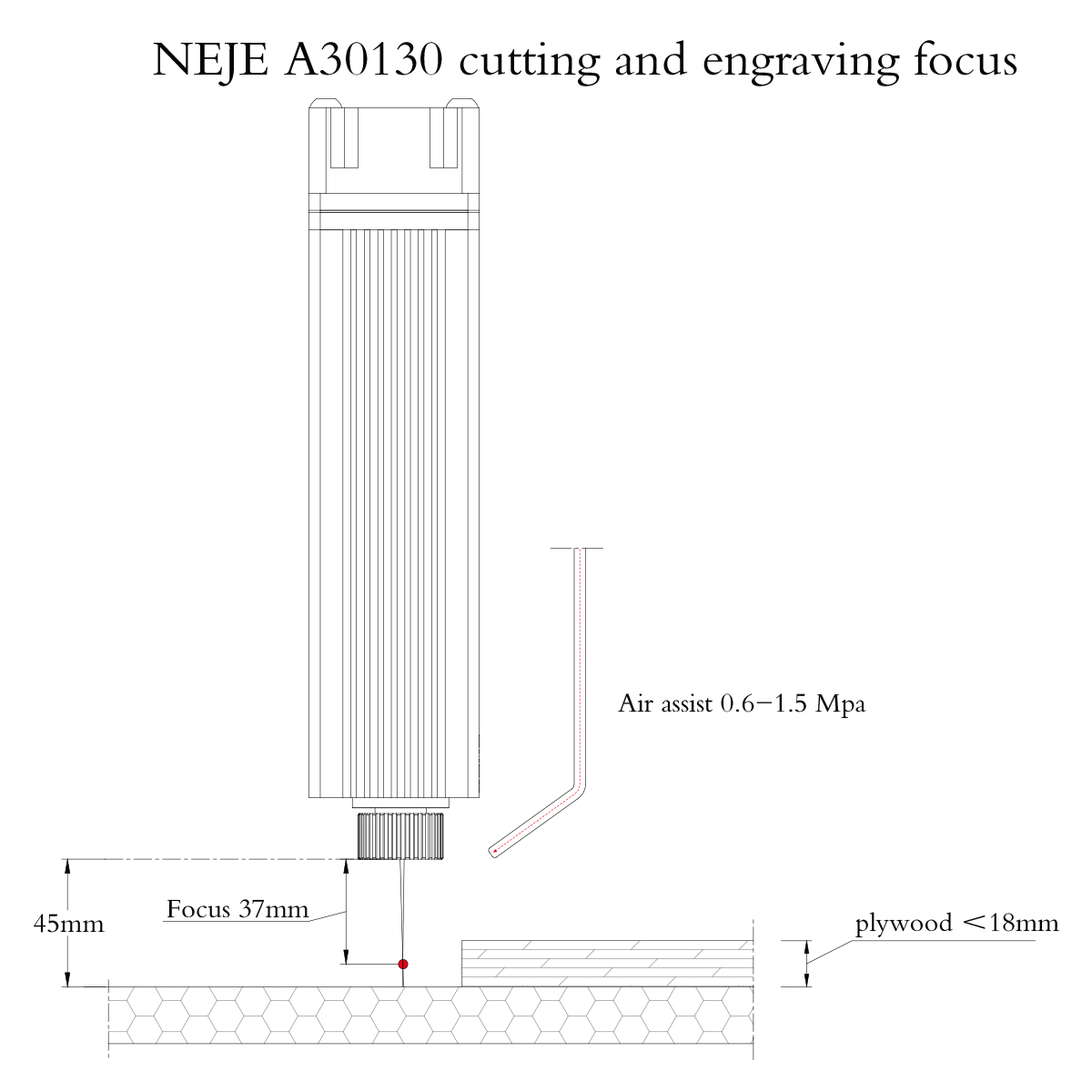

A30130

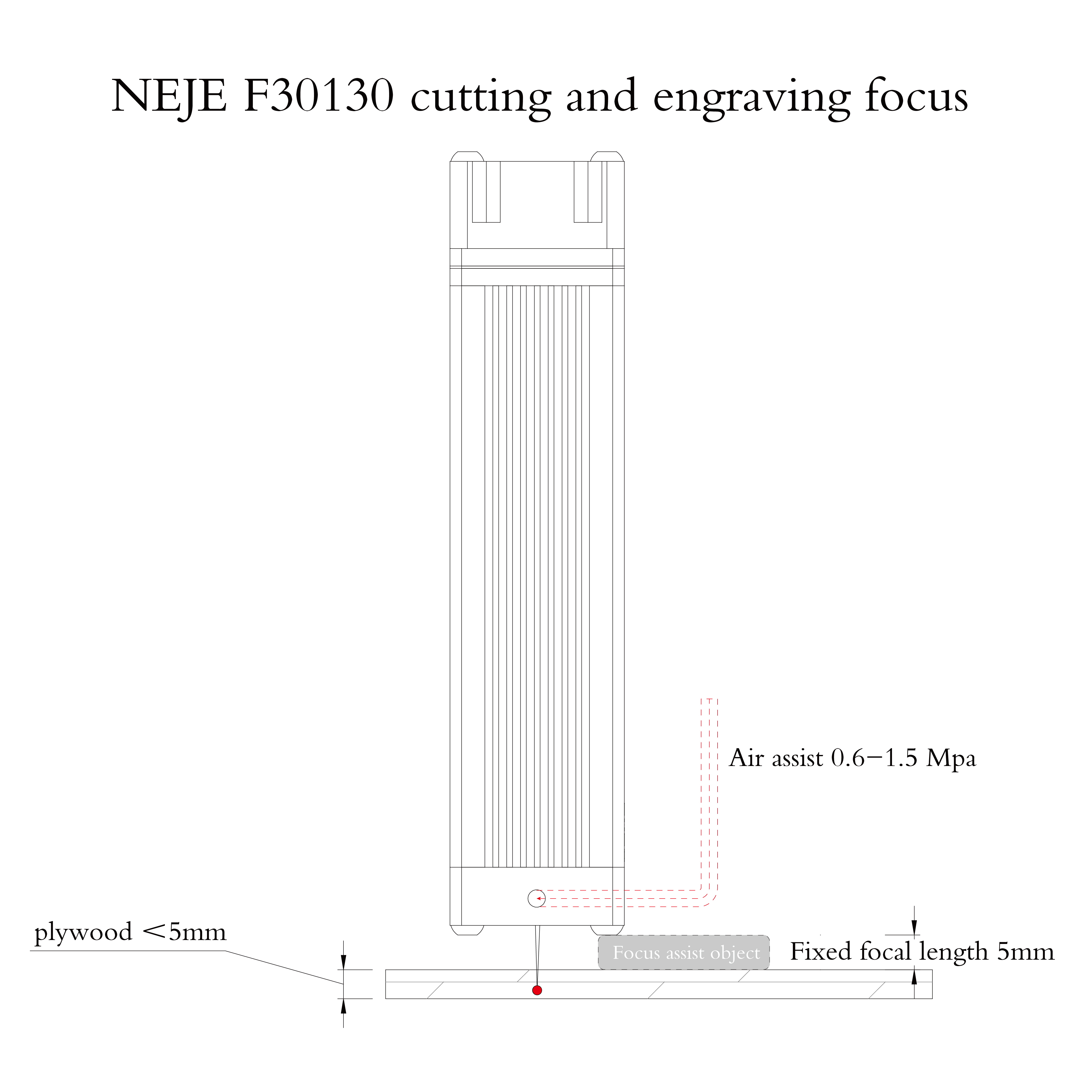

F30130

How to find focus

Find the best focus by rotating the lens. If it is a module with a fixed focus, it is enough to find the distance between the module and the object. Usually, we use a certain thickness of material to pad under the module to help find the best position.

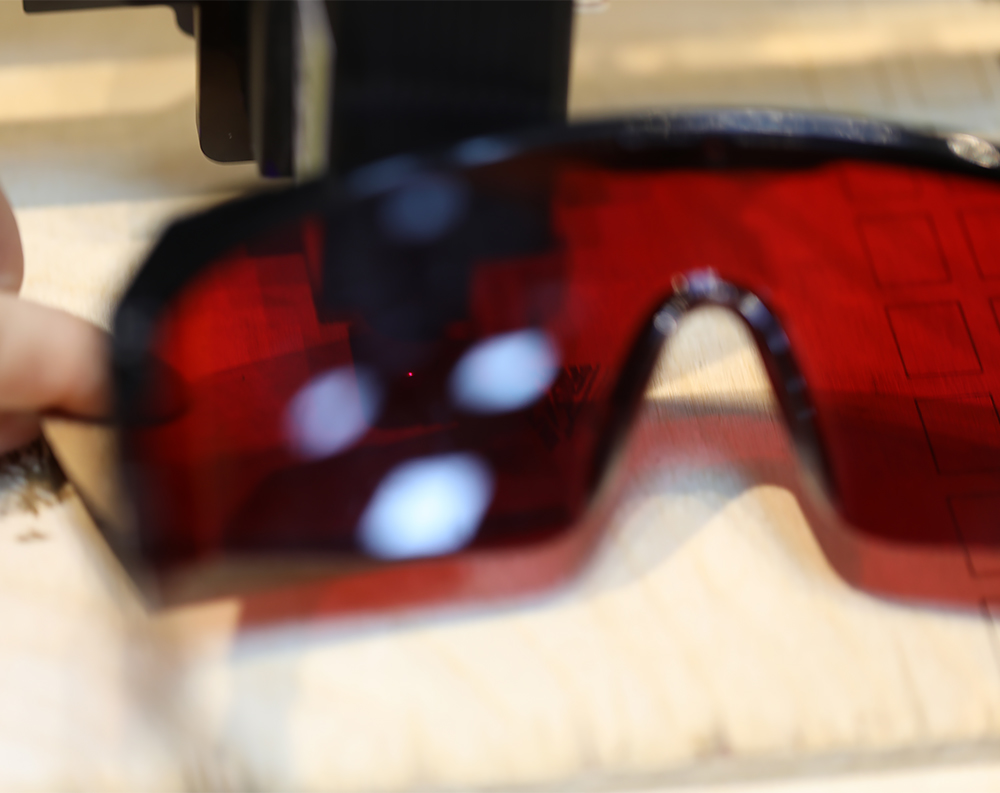

Adjust the suitable low light through the software. The NEJE mode can be adjusted in the “Settings” column of the NEJE Win software; the GRBL mode can be adjusted in the “Grbl Configuration” of the laserGRBL software, which has been explained above.

Put a gray cardboard on the surface of the white material (such as plywood) as a focus reference to find the precise focus. A fine focal point can be observed through the protective goggles or the shade of the module.

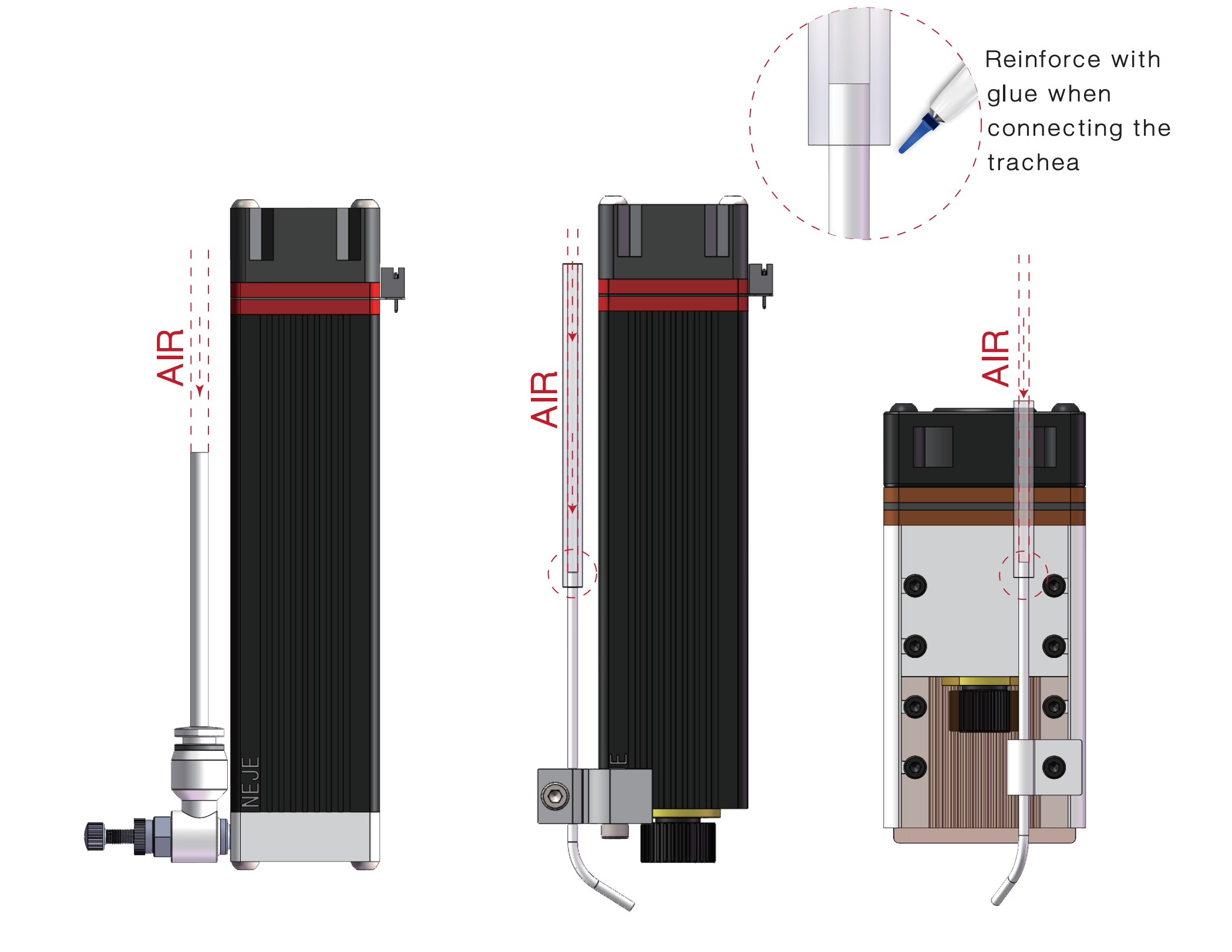

Install Air Assist

- Please make sure that the air outlet is aligned with the focus point;

- Cutting MDF board requires 0.6-1.5mPa air pressure to efficiently clean the carbonized material;

- The air-assisted module designed in the cavity, try to choose a clean origin, oily or unclean origin may be Causes the lens to be broken at high temperature;

- A40640 modules and modules with similar external air sources can work without air assistance, and the modules designed with the cavity must work under the conditions of increased air assistance, otherwise it is easy to contaminate the lens and cause the lens high temperature rupture;